Process Equipment

We ensure the purity of raw materials entering the production sites

Grinding

Production of powdered sugar. Grinding of defective cookies and bakery products

Mixing

Mixing of bulk and liquid products

Plasticization

Margarine plasticization

and dosing

Production of icing sugar

Powdered sugar is one of the key components in many products produced by confectionery factories. In mass production, it is much more convenient for a company to produce powdered sugar in-house rather than purchasing it ready-made.

Our company has extensive experience in manufacturing complexes for powdered sugar production.

Powdered sugar is one of the key components in many products produced by confectionery factories. In mass production, it is much more convenient for a company to produce powdered sugar in-house rather than purchasing it ready-made.

Our company has extensive experience in manufacturing complexes for powdered sugar production.

The mill is equipped with a rotor head that rotates at high speed to grind sugar into powder. The higher the rotation speed, the finer the powder is obtained.

After grinding, the powder is fed into a storage tank equipped with a special tedder, which prevents the product from sticking, as icing sugar is hygroscopic.

From the storage tank, powdered sugar can be discharged using a screw conveyor into process containers or directed to the receiving and transport line via a rotary feeder.

We offer comprehensive solutions that encompass both the feeding of sugar into the crusher and the transportation of powdered sugar to the designated point in the production line.

At the customer’s request, we equip powdered sugar production complexes with compact platforms that ensure convenient access and easy maintenance.

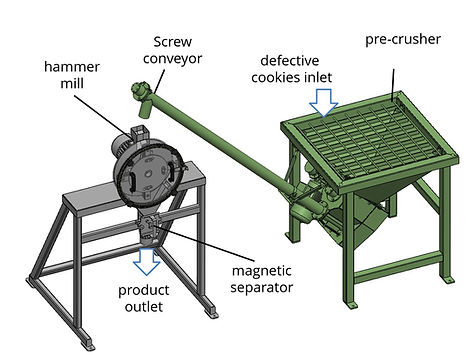

Сookies crusher machine handling

Unfortunately, no confectionery enterprise is free from defective products. Therefore, their processing is a highly relevant task that significantly reduces raw material losses.

For certain types of confectionery waste, we offer effective solutions.

Grinding is carried out in two stages. Pre-grinding takes place in the feed hopper where the cookies are loaded.

A magnetic separator is installed at the crusher outlet to capture ferromagnetic impurities.

The main grinding is done in the hammer crusher, to which the cookies are fed by an auger from the feed hopper. The hopper auger and the pre-chopper are driven by one gearmotor.

Complex for producing a homogeneous mixture of bakery products and water

Homogenization of bakery products with water is carried out in two stages.

In the mixer, the components are loaded in the required proportions and pre-ground. In the homogenizer-disperser, the main grinding takes place.

The mixer is mounted on a weighing system, ensuring the accurate loading of raw materials in the specified ratio. Water is supplied through a dosing-tempering unit, which mixes incoming streams of hot and cold water to achieve the desired temperature.

At the mixer outlet, a magnetic separator is installed to capture ferromagnetic impurities, along with a mesh filter to remove mechanical particles.

Homogenization of bakery products with water is carried out in two stages.

In the mixer, the components are loaded in the required proportions and pre-ground. In the homogenizer-disperser, the main grinding takes place.

The mixer is mounted on a weighing system, ensuring the accurate loading of raw materials in the specified ratio. Water is supplied through a dosing-tempering unit, which mixes incoming streams of hot and cold water to achieve the desired temperature.

At the mixer outlet, a magnetic separator is installed to capture ferromagnetic impurities, along with a mesh filter to remove mechanical particles.

Mixing

Mixing is one of the main technological processes in the food industry. This process is used in the production of many food products.

The peripheral speed of the ribbon shaft is approximately 1.5 m/s, and the desired mixing degree is typically achieved in about 15 minutes.

The mixer can be equipped with a jacket for heating or cooling.

It is important to note that this type of mixer is not recommended for components with a density above 560 kg/m³, as well as for brittle and viscous products.

Mixing is one of the key technological processes in the food industry. This process is involved in the production of many food products.

For mixing bulk products, we manufacture horizontal and vertical ribbon mixers.

Horizontal ribbon mixers are the most common type, characterized by their simple design and ease of maintenance.

The working element of such mixers is a horizontal ribbon shaft with oppositely directed helical spirals. Spirals of a smaller diameter (orange) direct the product from the center to the side walls of the housing, while spirals of a larger diameter (yellow) do the opposite — from the side walls to the center. As a result, product layers move in opposite directions, effectively mixing the contents.

Vertical ribbon mixers

A vertical ribbon mixer is particularly relevant when producing mixtures of different compositions and minimizing batch cross-contamination.

A high-speed turbo mixer can be installed in the conical section of the mixer to break up compacted product lumps and, if necessary, inject liquid flavorings or additives into the product.

Vertical ribbon mixers are structurally more complex but provide more complete product discharge compared to horizontal mixers.

The spiral of the ribbon shaft has only one direction, moving the product upwards. The product falls downwards under the influence of gravity. The mixing is achieved by the movement of product layers in opposite directions.

A vertical ribbon mixer is particularly relevant when producing mixtures of different compositions and minimizing batch cross-contamination.

A high-speed turbo mixer can be installed in the conical section of the mixer to break up compacted product lumps and, if necessary, inject liquid flavorings or additives into the product.

Liquid component

storage tank

For mixing liquid products, we manufacture tanks with low-speed frame agitators. They are used, for example, to maintain ready-made emulsions or suspensions in a stable state or to prepare starters.

We can manufacture such a tank with a jacket for heating or cooling the product, a weighing system for monitoring product quantity, and equip it with a pump suitable for the specific product.

Plasticization

Margarine and confectionery fat are some of the primary raw materials for confectionery factories. They typically arrive at the production facility in the form of cooled briquettes. In this form, they cannot be loaded directly into process equipment, as this may damage the working parts of mixing devices. Therefore, they undergo plasticization — converting them into a paste-like mass.

Traditionally, plasticization is carried out in so-called fat melters by heating the product. However, fat melters have several significant drawbacks:

-

Heating the product to relatively high temperatures, accelerating oxidation and rancidity.

-

High energy consumption.

-

Low productivity.

Margarine and confectionery fat are some of the primary raw materials for confectionery factories. They typically arrive at the production facility in the form of cooled briquettes. In this form, they cannot be loaded directly into process equipment, as this may damage the working parts of mixing devices. Therefore, they undergo plasticization — converting them into a paste-like mass.

Traditionally, plasticization is carried out in so-called fat melters by heating the product. However, fat melters have several significant drawbacks:

-

Heating the product to relatively high temperatures, accelerating oxidation and rancidity.

-

High energy consumption.

-

Low productivity.

We manufacture a margarine plasticization complex that eliminates the aforementioned drawbacks. In our system, plasticization is mainly carried out mechanically, keeping the temperature of the plasticized margarine below 30°C. Despite its relatively compact size and low energy consumption, the system’s throughput reaches up to 2500 kg/h.

Product briquettes are loaded into the screw zone of the plasticizer, where preliminary grinding and movement toward the second zone — the high-speed mixer — take place. In this zone, final plasticization occurs through multiple collisions with rapidly rotating pins.

Both zones are equipped with heating jackets to ensure the flow of residual product from the working elements.

In this form, the margarine is ready to be fed into the processing equipment. The entire process takes just a few minutes.

From the high-speed mixer, the plasticized margarine is fed into the margarine dosing unit, which is equipped with a weighing module. The specified portion of the product is then pumped from the dosing unit into the processing equipment.

The dosing unit is also equipped with a heating jacket to prevent the product from solidifying.